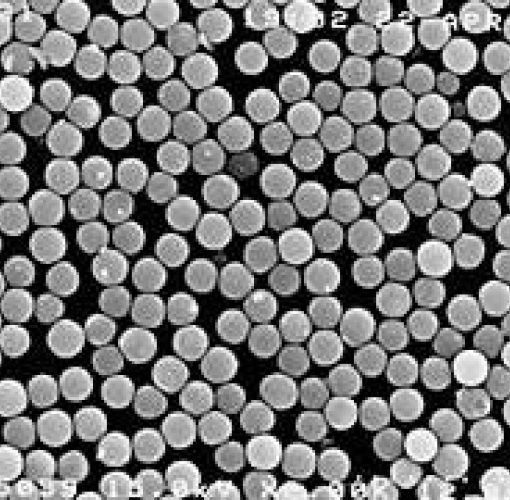

Antibacterial materials: using the huge specific surface area, surface multi mesoporous structure, super adsorption capacity and strange physical and chemical properties of nano-SiO2, functional ions such as silver ions are uniformly designed into the mesoporous on the surface of nano-si0x, which are stable, and the nano antibacterial powder with high efficiency, durability, high temperature resistance and broad-spectrum antibacterial is successfully developed (the particle size is only about 70 nm), Not only fill the domestic gap, but also the main technical indicators meet or exceed the similar products in Japan. After testing, when the concentration of nano antibacterial powder in water is only 0.315%, the antibacterial ability against gram-positive representative strains and gram-negative representative strains can be obviously revealed, and the antibacterial circle appears 2-3mm, and the antibacterial circle increases significantly with the increase of the concentration of nano antibacterial powder in water. According to the determination, when the Ag content in the water is 0.01mg/1, the Escherichia coli in the water can be completely killed, and no new flora can be produced for up to 90 days.

Nano antibacterial powder is applied to enamel glaze to produce drum washing machine with anti mildew and antibacterial function, and its antibacterial rate is more than 99%. It should be pointed out that the use conditions of nano antibacterial powder in enamel glaze are relatively harsh. It is necessary to maintain strong antibacterial properties in alkaline liquid and high temperature (about 900 ℃), which is unmatched by other antibacterial powders.

Nano antibacterial powder was added into interior wall coating to produce interior wall coating with long-term antibacterial and mildew proof function.

Nano antibacterial powder was used in women’s underwear detergent, wool, cashmere detergent, detergent and hand sanitizer. It was tested by the health and epidemic prevention department, and its antibacterial performance was very remarkable.

It can be predicted that with the enhancement of people’s health awareness, nano antibacterial powder will gradually be accepted by the general public of relevant application enterprises, and will emerge in bill, medical and health, chemical building materials, household appliances, functional fibers, plastic products and other industries.

Other applications

- Application in optical field

The application of nanoparticles in infrared reflective materials is mainly made into thin films and multilayer films. Nanoparticle film materials have a good application prospect in bulb industry. High pressure sodium lamps and various iodine arc lamps for photography require strong lighting, but 69% of the energy of the filament is converted into infrared after heating, which indicates that a considerable amount of electric energy is converted into heat energy and only a small part is converted into light energy for lighting. At the same time, the heating of the lamp tube will also affect the service life of the lamp. How to improve the luminous efficiency, Increasing illumination has always been a key problem to be solved. The birth of nanoparticles provides a new way to solve this problem. Since the 1980s, researchers and technicians have made multilayer interference films with nano-si0x and nano-TiO2 particles, with a total thickness of micron and lined on the inner wall of the bulb cover. As a result, they not only have good light transmittance, but also have strong infrared reflection ability. According to experts’ calculation, under the same light brightness, this kind of lamp can save 15% of electric energy compared with traditional halogen lamp.

- New organic glass additive

Plexiglass (PMMA) is commonly used as the window material of aircraft. When the aircraft flies at high altitude, the window material is easy to age after ultraviolet radiation, resulting in a decrease in transparency. In order to solve this problem, using the extremely strong ultraviolet reflection performance of nano si0x, the surface modified nano si0x is added in the production process of plexiglass, the anti ultraviolet radiation ability of the product is more than doubled, and the impact strength is increased by 80%.