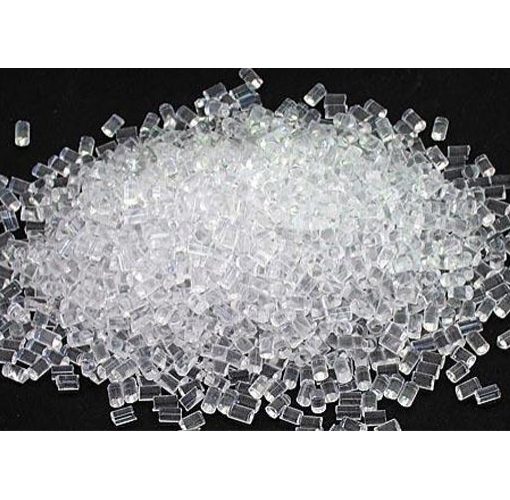

Chinese researchers have successfully extracted nano silica from rice husk, which is indispensable for the manufacture of rubber and plastics. According to the inventor of this technology, Professor Wang Zichen of the school of chemistry of Jilin University, because the components of rice husk contain a large amount of silicon, even if it is buried, it is difficult to be degraded in the soil, which is easy to cause changes in the composition of the land. Silica is an indispensable additive in plastics and rubber. It can increase the strength and transparency of plastic products. In the past, the extraction of silica mostly depended on the ore, but the composition of the ore was complex, and multiple processes were needed to remove impurities in order to extract the required components. In addition, the extracted ore waste residue can not be recovered better, which has become a threat to the environment. After years of research, Wang Zichen successfully used the characteristics of silicon rich in rice husk to extract silicon dioxide from rice husk by removing inorganic substances, fibers and impurities and burning to remove carbon components, which accounts for about one fifth of rice husk. There is no waste in this process, all rice husks are fully utilized, and in the process of carbon removal, carbon can be retained through certain procedures to become the raw material of activated carbon. It is understood that most of the silica processed from ore is micron silica, while rice husk is nano silica, with a molecular volume of 1% of micron. Therefore, its strength and transparency are stronger than micron silica, but the cost is much less. At present, this technology is preparing for large-scale application in production.