FRP products

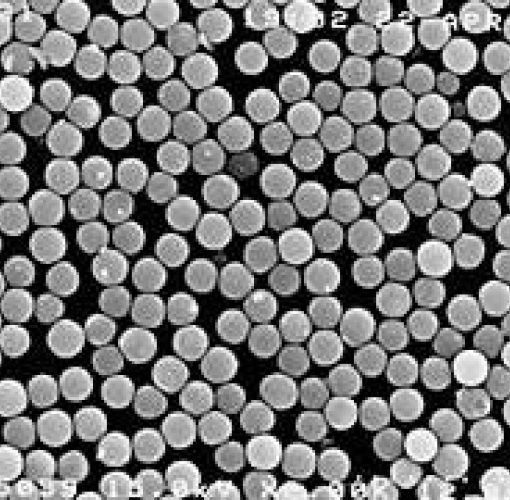

Although FRP products have the advantages of light weight, high strength and corrosion resistance, they have low hardness and poor wear resistance. Relevant experts added nano-SiO2 to gel coat resin through ultrasonic dispersion method, and compared it with gel coat without nano-SiO2. It was found that the Mohs hardness increased from 2.2 (equivalent to the hardness of gypsum) to 2.8 ~ 2.9 (Level 3 is the hardness of natural marble), and the wear resistance increased by 1 ~ 2 times. Due to the grafting and bonding between nanoparticles and organic polymers, The toughness of the material is increased, so the tensile strength and impact strength are more than doubled, and the heat resistance is also greatly improved.

With the rapid growth of municipal solid waste and the increasingly serious environmental pollution, it is urgent to strengthen the elimination of “four pests” and prevent the spread of diseases. Painting lime on the trunk and spraying liquid medicine into the dustbin have little effect. Now, spraying central nervous anesthetic insecticides has been used in big cities to eliminate insect pests such as mosquitoes, flies and cockroaches. However, most of these insecticides are imported from abroad, the price is high, and the validity period after spraying is short (only one month). Nano SiO2 is used as the carrier to adsorb this kind of insecticide, which has a good slow-release effect. According to the measurement, the validity period after spraying is more than one year.

Cosmetics

For cosmetics, it is required to have strong ultraviolet shielding ability. It is best to protect not only the harm of ultraviolet medium wave (UVB) to human body, but also the long wave of ultraviolet (UVA). In essence, UV shielding includes two aspects: one is the absorption of UV as mentioned above, and the other is the reflection of UV. At present, the anti UV agents developed from the perspective of UV reflection performance have not been reported in the world. In the past, organic compounds were often used as ultraviolet absorbers in sunscreen products, but there were problems such as increasing the amount of additives in order to protect the skin from ultraviolet rays as much as possible, which would increase the occurrence of skin cancer and chemical allergy. Nano SiO2 was an inorganic component, which was easy to be compatible with other components of cosmetics, non-toxic and tasteless, It is white and can be simply colored. In particular, nano-SiO2 has strong UV reflection ability and good stability. It will not decompose, change color or react with other components in the formula after being irradiated by UV. These outstanding characteristics of Nano-SiO2 have laid a good foundation for the upgrading of sunscreen cosmetics.