ceramics

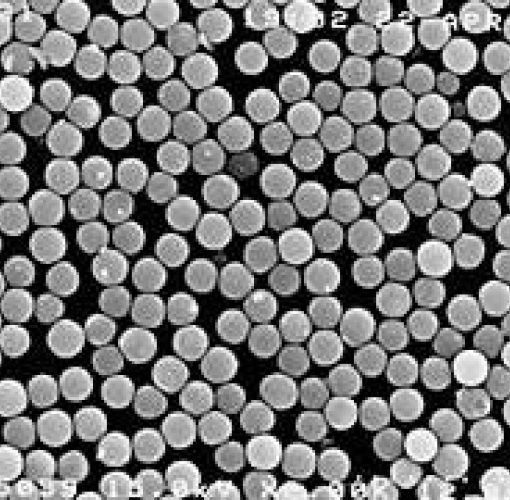

Adding nano-SiO2 instead of nano-a1203 to 95 porcelain can not only play the role of nano particles, but also be the particle of the second phase. It not only improves the strength and toughness of ceramic materials, but also improves the hardness and elastic modulus of materials. Its effect is more ideal than adding A1203. Using nano-SiO2 to composite ceramic substrate not only improves the compactness, toughness and finish of the substrate, but also greatly reduces the sintering temperature. In addition, the application effect of Nano-SiO2 in ceramic products such as ceramic filter screen and corundum ball is also very significant.

Sealant, adhesive

Sealant and binder are important products with large quantity, wide range and wide application range. It requires the product viscosity, fluidity and curing speed to reach the best conditions. China’s products in this field are relatively backward, and high-grade sealants and adhesives rely on imports. Foreign products in this field have used nano materials as modifiers, and nano-SiO2 is the preferred material. It mainly coats a layer of organic material on the surface of Nano-SiO2 to make it hydrophobic. When it is added to the sealant, it will soon form a silica structure, that is, nano-si0x small particles form a network structure, inhibit colloidal flow, accelerate curing speed and improve bonding effect, Due to the small size of nano-SiO2 particles, the sealing and impermeability of the product are also increased.